CRYOGENIC GLOBE VALVE DJ A K

Price 30-50 USD ($)/ Unit

CRYOGENIC GLOBE VALVE DJ A K Specification

- Weight

- Depends on Valve Size

- Noise Level

- Low

- Automatic Grade

- Manual

- Thickness

- Body Wall: As per Standard

- Color

- Metallic Silver

- Control System

- Handwheel / Actuator

- Processing Type

- Forged / Cast

- Application

- Cryogenic Service, LNG, Liquid Oxygen, Nitrogen, Hydrogen

- Size

- to 12 (DN15 to DN300)

- Material

- Stainless Steel / Cryogenic Grade

- Capacity

- Depends on Valve Size

- Stem Type

- Rising Stem

- End Connection

- Flanged, Welded, Threaded

- Leakage Class

- Class VI / Tight Shut-off

- Pressure Rating

- 150#, 300#, 600#

- Face to Face Dimension

- As per ASME/BS/DIN Standards

- Fire Safe Design

- Available

- Temperature Range

- -196°C to +80°C

- Design Standard

- BS 6364 / API 602 / ASME B16.34

- Bonnet Type

- Extended Bonnet for Cryogenic Application

- Flow Direction

- Bi-directional

- Packing

- Graphite / PTFE / Cryogenic Service Packing

- Testing

- Hydrostatic, Cryogenic Test as per Standard

- Seat Type

- Metal Seated / Soft Seated (PTFE, PCTFE)

- Operation

- Manual, Pneumatic, Electric

CRYOGENIC GLOBE VALVE DJ A K Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- SHANGHAI

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden box

- Main Export Market(s)

- South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Australia, Africa

- Main Domestic Market

- All India

- Certifications

- CE

About CRYOGENIC GLOBE VALVE DJ A K

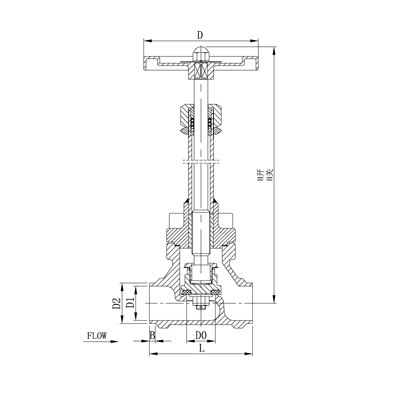

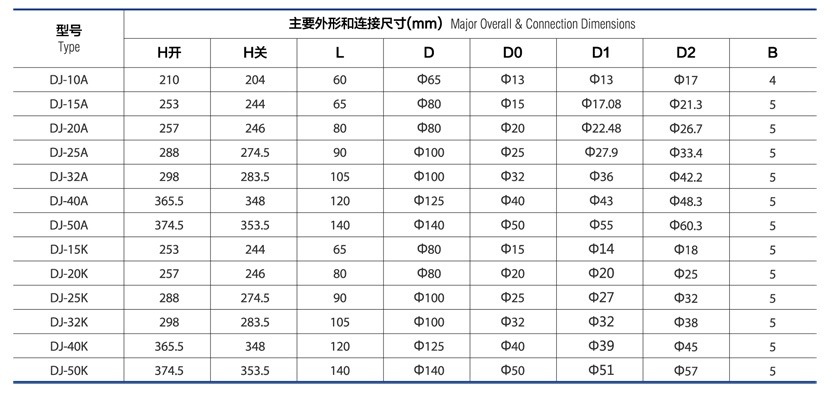

CRYOGENIC GLOBE VALVE DJ-A/K

Nominal Pressure: 4.0Mpa

Design Temperature: -40ai12+80a

Suitable Media: LNG, LO2, LN2, LAr, CO2

Connection: Butt Weld

Materials of Main Parts:

Body, Cover: CF8

Disc, Stem: S30408

Disc Seals: PCTFE

Precision for Extreme Environments

The CRYOGENIC GLOBE VALVE DJ A K is crafted to ensure optimal flow control under challenging, cryogenic conditions. Its extended bonnet design minimizes heat transfer and preserves stem packing integrity, making it the ideal solution for industries handling LNG and other low-temperature fluids. With options for soft or metal seats, it ensures leak-tight service and long-term durability.

Versatile End Connections and Operation

Users can select from flanged, welded, or threaded end connections, aligning with varied piping setups. The valve's robust construction permits both manual and automated control, featuring compatibility with handwheels or actuators for superior operational flexibility.

Built to International Standards

Each valve is manufactured to comply with stringent standards including BS 6364, API 602, and ASME B16.34, ensuring reliability, safety, and quality performance. Extensive testing procedures, including hydrostatic and cryogenic assessments, guarantee dependable operation even in the harshest environments.

FAQ's of CRYOGENIC GLOBE VALVE DJ A K:

Q: How does the extended bonnet design benefit cryogenic applications?

A: The extended bonnet keeps the packing area above the cold zone, significantly reducing the risk of ice formation and preserving the valve's sealing integrity at extremely low temperatures. This design is critical for cryogenic services such as LNG or liquid gases.Q: What end connections are available for the CRYOGENIC GLOBE VALVE DJ A K?

A: This valve comes with several end connection options, including flanged, welded, and threaded types. This flexibility enables integration into various piping systems and installation scenarios depending on your operational needs.Q: When should I choose a metal seated versus a soft seated (PTFE/PCTFE) valve?

A: Metal seats are ideal for applications requiring higher durability and can handle more abrasive, high-pressure, or high-temperature environments. Soft seats (PTFE/PCTFE) deliver tighter shut-off and are preferred where chemical compatibility and superior sealing are paramount.Q: Where can CRYOGENIC GLOBE VALVE DJ A K be installed?

A: Designed for cryogenic service, this valve is widely used in applications such as LNG processing, liquid oxygen, nitrogen, hydrogen transfer, and other low-temperature industrial processes. It is suitable for both new installations and retrofits in these sectors.Q: What testing processes does the valve undergo before delivery?

A: Each CRYOGENIC GLOBE VALVE DJ A K is rigorously tested to hydrostatic and cryogenic standards, ensuring safe operation and compliance with BS, ASME, and API formats. Testing confirms performance under extreme conditions and certifies leak-tight integrity.Q: How is the valve operated and controlled?

A: The valve is available with manual handwheel operation or can be equipped with pneumatic or electric actuators for automated control. This range of control systems allows users to choose the most suitable operation method for their specific process requirements.Q: What advantages does using a cryogenic globe valve provide for industrial applications?

A: The main benefits include reliable bi-directional shut-off, low leakage (Class VI), resistance to thermal shocks, and compatibility with a broad temperature range. These characteristics make the CRYOGENIC GLOBE VALVE DJ A K a robust choice for cryogenic and ultra-low temperature fluid handling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in cryogenic globe valve Category

cryogenic globe valve DJ 15P6 P10

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Application : Cryogenic Service, LNG, Liquid Nitrogen, Oxygen, Argon

Capacity : Designed as per application (custom flow rate)

Processing Type : Forged/Integral

Size : DN15 (1/2 Inch)

cryogenic globe valve DJ 15 PC

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Application : Cryogenic fluid control in LNG, oxygen, nitrogen & industrial gas pipelines

Capacity : High or as per requirement

Processing Type : Casting

Size : 15 mm (1/2 inch) and other sizes available

CRYOGENIC VALVE DJ 10PY PY1

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Application : Cryogenic Gas/Liquid Control

Capacity : Suitable for Cryogenic Media

Processing Type : Cryogenic Service

Size : DN10 (10mm)

CRYOGENIC GLOBE VALVE DJ 10 15 20 25 40 (NPT)

Price Range 10.00 - 100.00 USD ($) / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Liquefied gases, Industrial Cryogenic Systems, LNG, Liquid Nitrogen, Oxygen, Argon, Air, Helium, etc.

Capacity : Suitable for Pressure up to 40 bar

Processing Type : Cryogenic Service

Size : DJ 10, DJ 15, DJ 20, DJ 25, DJ 40 (Corresponds to 3/8, 1/2, 3/4, 1, 11/2 NPT)

|

ZHANGJIAGANG GRANDE MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry