CRYOGENIC GLOBE VALVE DJ 10 15 20 25 40 (NPT)

CRYOGENIC GLOBE VALVE DJ 10 15 20 25 40 (NPT) Specification

- Color

- Metallic Silver

- Capacity

- Suitable for Pressure up to 40 bar

- Noise Level

- Low

- Processing Type

- Cryogenic Service

- Control System

- Handwheel Operated

- Application

- Liquefied gases, Industrial Cryogenic Systems, LNG, Liquid Nitrogen, Oxygen, Argon, Air, Helium, etc.

- Size

- DJ 10, DJ 15, DJ 20, DJ 25, DJ 40 (Corresponds to 3/8, 1/2, 3/4, 1, 1-1/2 NPT)

- Thickness

- Robust Body, Wall Thickness as per Standard

- Weight

- Depends on Size (Approx. 0.8kg to 3.5kg)

- Automatic Grade

- Manual

- Material

- Stainless Steel (SS304/SS316/CF8M) or Brass

- Seat Type

- Metal to Metal / PTFE

- Packing

- PTFE / Graphite

- Face to Face Dimension

- As per Manufacturer Standard

- Body Type

- Straight Pattern

- Bonnet Type

- Extended Bonnet for Cryogenic Use

- Valve Test

- Hydrostatic & Pneumatic Test

- Design Standard

- BS 6364 / API 602

- End Connection

- NPT (National Pipe Thread)

- Stem Type

- Rising Stem

- Temperature Range

- -196C to +80C

- Port Size Options

- (DJ10), (DJ15), 1 (DJ20), 1 (DJ25), 1 (DJ40)

- Pressure Rating

- Class 150 to Class 600

- Leakage Class

- ANSI B16.104 Class VI

- Operation Type

- Wheel / Hand Operated

CRYOGENIC GLOBE VALVE DJ 10 15 20 25 40 (NPT) Trade Information

- Minimum Order Quantity

- 100 Kilograms

- FOB Port

- SHANGHAI

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 50 Kilograms Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden box

- Main Domestic Market

- All India

- Certifications

- CE

About CRYOGENIC GLOBE VALVE DJ 10 15 20 25 40 (NPT)

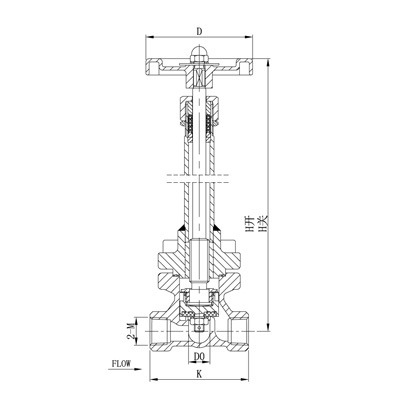

CRYOGENIC GLOBE VALVE DJ-10/15/20/25/40(NPT)

Nominal Pressure: 4.0Mpa

Design Temperature: -196+80

Suitable Media: LNG, LO2, LN2, LAr, CO2

Materials of Main Parts:

Body, Cover: CF8

Disc, Stem: S30408

Disc Seals: PCTFE

Reliable Operation in Extreme Cold

Designed for cryogenic service, the DJ Series Globe Valves provide secure shut-off and tight sealing in environments ranging from -196C to +80C. Their extended bonnet ensures reliable insulation and smooth operation in applications such as LNG plants and industrial cryogenic systems, where extreme temperatures are common.

Flexible Port Sizes and Pressure Ratings

With port sizes from (DJ10) to 1 (DJ40) and pressure ratings up to Class 600 (40 bar), these valves address the diverse needs of industrial, medical, and gas processing operations. Their robust stainless steel or brass construction, in compliance with international standards, ensures long-term durability and safety.

FAQs of CRYOGENIC GLOBE VALVE DJ 10 15 20 25 40 (NPT):

Q: How does the extended bonnet design benefit cryogenic applications?

A: The extended bonnet on the DJ Series Cryogenic Globe Valve protects the stem and packing from direct exposure to extremely cold media, preventing ice formation and providing safer and more reliable valve operation even at temperatures as low as -196C.Q: What types of gases and applications are these valves suitable for?

A: These valves are ideal for controlling the flow of liquefied gases such as LNG, nitrogen, oxygen, argon, air, and helium. Typical applications include industrial cryogenic systems, gas plants, and medical or laboratory environments requiring precise, leak-proof control.Q: When should a metal-to-metal seat be selected over PTFE?

A: A metal-to-metal seat is recommended for higher temperature or abrasive applications where maximum durability is necessary, while PTFE seats are preferred for enhanced sealing in ultra-low temperature operations or when chemical compatibility is required.Q: Where are DJ Series Cryogenic Globe Valves typically installed?

A: These valves are commonly installed in pipelines, storage tanks, vaporizing stations, and distribution manifolds in settings such as chemical facilities, LNG terminals, and hospital gas supply systems.Q: What process and quality standards do these valves adhere to?

A: The DJ Series valves are designed and manufactured according to BS 6364 and API 602 standards, ensuring they comply with stringent requirements for cryogenic isolation valves. Each valve undergoes hydrostatic and pneumatic testing and meets ANSI B16.104 Class VI leakage requirements.Q: How is the valve operated, and can it be automated?

A: The CRYOGENIC GLOBE VALVE DJ Series is manually operated using a wheel or handwheel mechanism, providing precise flow control for critical cryogenic services. Automation is not standard but may be customized upon request.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in cryogenic globe valve Category

cryogenic globe valve DZJ

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Capacity : High flow capacity

Color : Silver / Metallic

Processing Type : Forged

Noise Level : Low

cryogenic globe valve DJS 25 A1

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Capacity : 25 mm (Port Size)

Color : Metallic Silver

Processing Type : Forged

Noise Level : Low

cryogenic globe valve DZJ 65

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Capacity : DN65 (2.5 Inches)

Color : Metallic Silver

Processing Type : Cryogenic Valve

Noise Level : Low

CRYOGENIC GLOBE VALVE DJ GGY

Minimum Order Quantity : 1 Watt

Capacity : Up to DN600

Color : Metallic Silver / Blue Actuator

Processing Type : Forged / Cast

Noise Level : Low

|

ZHANGJIAGANG GRANDE MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry