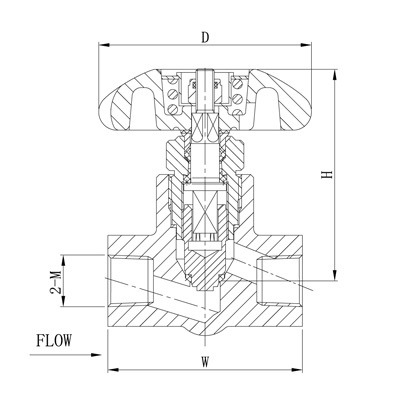

cryogenic globe valve DJ 10PA PB PC

cryogenic globe valve DJ 10PA PB PC Specification

- Noise Level

- Low

- Color

- Silver

- Capacity

- Class 150800

- Material

- Stainless Steel / Forged Steel

- Weight

- Depends on Size

- Control System

- Handwheel Operated

- Size

- DN10 to DN200

- Automatic Grade

- Manual

- Processing Type

- Cryogenic Service

- Thickness

- Industry Standard

- Application

- LNG, Liquid Nitrogen, Oxygen, and other cryogenic fluids

- Media

- Liquefied Gases: Oxygen, Nitrogen, Argon, LNG, CO2

- Design Standard

- BS 6364, ASME B16.34

- End Connection

- Butt Weld, Socket Weld, Flanged

- Bonnet Type

- Extended Bonnet for Cryogenic Applications

- Surface Finish

- Polished

- Pressure Rating

- PN16 to PN63

- Operation

- Manual / Gear Operated Option

- Body Test Pressure

- 1.5 times rated pressure

- Type

- Cryogenic Globe Valve

- Packing

- Special Cryogenic Packing

- Leakage Class

- ANSI Class VI

- Temperature Range

- -196°C to +80°C

- Seat & Seal

- PTFE / Metal

- Stem Type

- Rising Stem

- Model

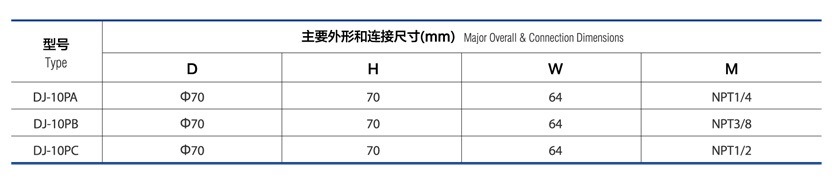

- 10PA / PB / PC

cryogenic globe valve DJ 10PA PB PC Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- SHANGHAI

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden box

- Main Domestic Market

- All India

- Certifications

- CE

About cryogenic globe valve DJ 10PA PB PC

Nominal Pressure:4.0Mpa

Design Temperature: -196-Suitable Media: LNG, LO2, LN2, LAr, CO2

Materials of Main Parts:

Body: HPb59-1

Stem: HPb59-1

Handwheel: ZL102

Disc Seals: PCTFE

Extended Bonnet and Reliable Sealing

The valve is equipped with an extended bonnet, providing optimal insulation for cryogenic service and ensuring operator safety. The PTFE or metal seat options paired with special cryogenic packing guarantee enhanced sealing integrity and minimized leakage, even under demanding low-temperature operations.

Versatile End Connections and Seat Types

Available in butt weld, socket weld, and flanged variants, the DJ 10PA PB PC accommodates diverse installation requirements. Choices of PTFE or metal seat materials allow users to select the best combination for their application, balancing chemical compatibility, durability, and sealing performance.

Certified Performance and Quality Standards

Manufactured in accordance with BS 6364 and ASME B16.34, each valve is subjected to rigorous body test pressures at 1.5 times the rated value, ensuring reliability. The polished surface finish and low-noise operation exemplify the attention to both durability and practicality demanded by cryogenic applications.

FAQs of cryogenic globe valve DJ 10PA PB PC:

Q: How does the DJ 10PA PB PC Cryogenic Globe Valve maintain leak-tight performance at extremely low temperatures?

A: This valve incorporates special cryogenic packing and PTFE/metal seating, engineered for optimal seal tightness and low-leakage (ANSI Class VI), even at temperatures as low as -196C.Q: What installation options are available for this cryogenic globe valve?

A: End connection choices include butt weld, socket weld, and flanged types, ensuring compatibility with a wide range of piping systems in industrial cryogenic applications.Q: When should I consider using the DJ 10PA PB PC valve with a manual versus gear operated handwheel?

A: Manual operation is suitable for standard sizes and infrequent actuation, while gear operation is advantageous for larger valves or applications requiring smoother, easier handling under higher pressure or torque conditions.Q: Where can this globe valve be used effectively?

A: The DJ 10PA PB PC valve is ideal for use in applications involving liquefied gases, including LNG, liquid nitrogen, oxygen, argon, and CO2commonly found in energy, chemical, and industrial gas sectors.Q: What is the process for ensuring valve quality and reliability before shipment?

A: Each valve undergoes testing at 1.5 times its rated body pressure, according to BS 6364 and ASME B16.34 standards, guaranteeing safety and performance under demanding operating conditions.Q: How does the extended bonnet design benefit cryogenic service?

A: The extended bonnet allows safe operation by insulating the actuator from extremely cold temperatures, reducing the risk of icing and ensuring long-term reliability in cryogenic environments.Q: What are the main advantages of using the DJ 10PA PB PC Cryogenic Globe Valve?

A: Key benefits include robust performance in low-temperature environments, minimal leakage, versatile installation options, compliance with strict international standards, and durable stainless or forged steel construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in cryogenic globe valve Category

cryogenic globe valve GP

Price 30-50 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Thickness : Body Thickness as per ASME Standards

Application : Cryogenic Service, Industrial Gas, LNG, Liquid Oxygen, Nitrogen, Argon applications

Weight : Varies by Size

cryogenic globe valve020

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Thickness : Standard as per design

Application : Cryogenic Liquid, LNG, Liquid Nitrogen, Oxygen, Argon Systems

Weight : Depends on size

CRYOGENIC GLOBE VALVE DJ GGY

Price 30-50 USD ($) / Unit

Minimum Order Quantity : 1 Watt

Thickness : As per Design Standard

Application : Cryogenic Service for LNG, Liquid Oxygen, Nitrogen, Hydrogen

Weight : Varies with Size

CRYOGENIC VALVE DJ 10PY PY1

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Thickness : Heavy Duty Construction

Application : Cryogenic Gas/Liquid Control

Weight : Approx. 1.2 kg

|

ZHANGJIAGANG GRANDE MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry