cryogenic globe valve GP

Price 30-50 USD ($)/ Unit

cryogenic globe valve GP Specification

- Processing Type

- Forged / Cast

- Color

- Metallic / Silver

- Capacity

- Designed for Cryogenic Applications

- Size

- Range: 15 mm to 300 mm (1/2 to 12)

- Thickness

- Body Thickness as per ASME Standards

- Automatic Grade

- Manual

- Application

- Cryogenic Service, Industrial Gas, LNG, Liquid Oxygen, Nitrogen, Argon applications

- Material

- Stainless Steel (SS 304/316), Carbon Steel, Brass

- Noise Level

- Low

- Control System

- Handwheel Operated

- Weight

- Varies by Size

- Test Standard

- As per API 598 / BS 6364

- Body Construction

- One Piece or Two Piece Forged / Cast Body

- Bonnet Type

- Extended Bonnet for Cryogenic Applications

- Pressure Rating

- Class 150, 300, 600

- Stem Type

- Rising Stem with Backseat Arrangement

- Operation

- Manual Handwheel (Optional: Actuated)

- Packing

- PTFE / Graphite / Cryogenic Special Stem Sealing

- Design Standard

- BS 6364, API 602 / ASME B16.34

- Type

- Globe Valve (GP Series)

- End Connection

- Flanged, Butt Weld, Socket Weld, Screwed Ends

- Operating Temperature Range

- as low as -196°C (suitable for Liquid Oxygen/Liquid Nitrogen/etc.)

- Leakage Class

- ANSI Class VI

cryogenic globe valve GP Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- SHANGHAI

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden box

- Main Domestic Market

- All India

- Certifications

- CE

About cryogenic globe valve GP

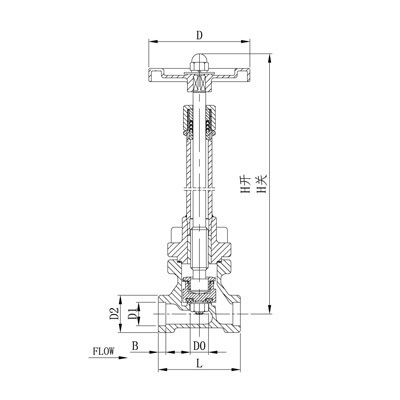

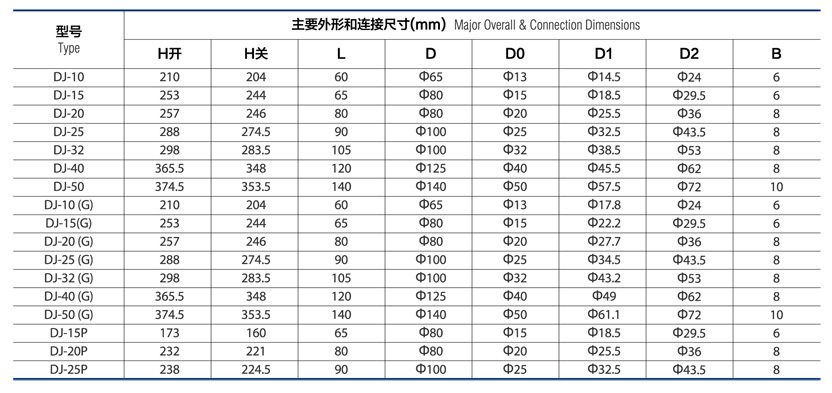

CRYOGENIC VALVE DJ (GP)

Nominal Pressure: 4.0Mpa

Design Temperature: -196A A12A+80AAA

Suitable Media: LNG, LO2, LN2, LAr,A CO2

Connection: Socket Weld

Materials of Main Parts:

Body, Cover: CF8

Disc, Stem: S30408

Disc Seals: PCTFE

Advanced Cryogenic Performance

Designed for use with extremely low temperatures (down to -196C), the GP Series Globe Valve features an extended bonnet and cryogenic-specific stem sealing, ensuring superior operational safety and isolation. Its robust construction and compliance with BS 6364 and API 602 standards make it the go-to choice for critical cryogenic applications in industrial gas and LNG sectors.

Flexible Connection and Size Options

Offered in a variety of end connection types-including flanged, butt weld, socket weld, and screwed-the valve is adaptable to multiple installation requirements. Sizes range from 15mm up to 300mm, suiting both compact and large-scale cryogenic systems. This versatility streamlines integration into new and existing piping setups for various gases.

Durable Material Selection

Constructed from high-grade stainless steel (SS 304/316), carbon steel, or brass, every GP Series Globe Valve promises longevity and resistance against low-temperature embrittlement. Body thickness adheres to ASME standards and is available in one- or two-piece cast or forged variants, ensuring optimal strength for demanding operating environments.

FAQ's of cryogenic globe valve GP:

Q: How does the GP Series Cryogenic Globe Valve ensure leak-tight operation at extremely low temperatures?

A: The GP Series utilizes an extended bonnet, rising stem with backseat arrangement, and specialized cryogenic stem sealing options (PTFE, graphite, or cryogenic grades) to maintain leak-tight service even at temperatures as low as -196C, complying with ANSI Class VI leakage standards.Q: What end connections and pressure ratings are available for this valve series?

A: The GP Series Cryogenic Globe Valve can be supplied with flanged, butt weld, socket weld, or screwed ends, and supports pressure ratings of Class 150, 300, and 600, accommodating diverse piping systems and requirements.Q: When should stainless steel, carbon steel, or brass material be selected for these valves?

A: Material selection should be based on the media fluency, compatibility with process fluids, and operating temperatures. Stainless steel is preferred for aggressive or ultra-cold applications; carbon steel suits less demanding cryogenic service; brass is used for specific industrial gas requirements.Q: Where are these valves commonly installed and used?

A: Cryogenic Globe Valves from the GP Series are typically used in industrial settings dealing with cryogenic fluids-such as LNG plants, medical gas suppliers, chemical and gas distribution facilities, and other installations handling liquid oxygen, nitrogen, or argon.Q: What is the process for installing and operating a GP Series valve?

A: Installation involves selecting the correct size and compatible end connections, ensuring alignment per ASME and API standards, and mounting the valve. Operation is manual via handwheel, but actuated options are available. Periodic maintenance checks ensure optimal sealing and performance.Q: What benefits does the extended bonnet provide for cryogenic applications?

A: An extended bonnet isolates the valve packing and stem from extreme cold, reducing condensation and thermal shock, while ensuring reliable actuator and sealing performance at cryogenic temperatures.Q: What testing standards and leakage classes are followed during manufacturing?

A: Each GP Series valve is tested to API 598 and BS 6364 requirements, guaranteeing high reliability and safety. Leakage class meets ANSI Class VI specifications, ensuring minimal to zero permissible leakage in cryogenic service.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in cryogenic globe valve Category

cryogenic globe valve110

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Processing Type : Forged

Size : 1/2 inch to 12 inch (DN15 DN300)

Color : Metallic Grey

Capacity : Up to 110 bar

cryogenic globe valve DJS 25 A1

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Processing Type : Forged

Size : DN25 (25 mm), Custom sizes available

Color : Metallic Silver

Capacity : 25 mm (Port Size)

cryogenic globe valve DJ 15 PC

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Processing Type : Casting

Size : 15 mm (1/2 inch) and other sizes available

Color : Metallic Silver

Capacity : High or as per requirement

cryogenic globe valve DZJ 40J

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Processing Type : Cryogenic fluid regulation

Size : DN40 (40 mm)

Color : Metallic Silver

Capacity : Suitable for low and medium pressure applications

|

ZHANGJIAGANG GRANDE MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry