CRYOGENIC GLOBE VALVE DJ NPT

CRYOGENIC GLOBE VALVE DJ NPT Specification

- Capacity

- Suitable for Cryogenic Applications

- Application

- Cryogenic Service, Liquid Oxygen, Nitrogen, LNG, Industrial Gases

- Processing Type

- Forged

- Control System

- Hand Operated

- Thickness

- Body Wall as per ASME B16.34

- Weight

- Varies by Size

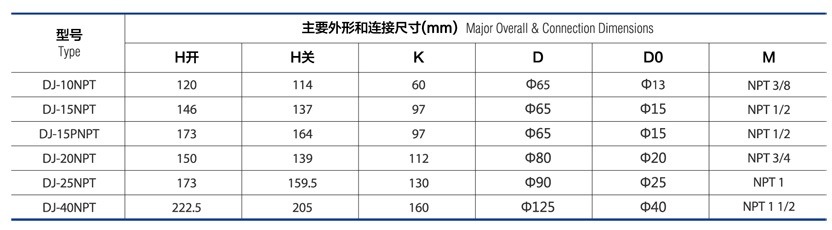

- Size

- 1/2 inch to 2 inch

- Noise Level

- Low

- Automatic Grade

- Manual

- Material

- Stainless Steel / CF8 / CF8M

- Color

- Metallic Silver

- End Connection

- DJ NPT (Double Jointed National Pipe Thread)

- Seat Type

- Soft Seat / Metal Seat

- Testing Standard

- API 598 / BS 6755

- Pressure Rating

- Class 150 - Class 800

- Operation

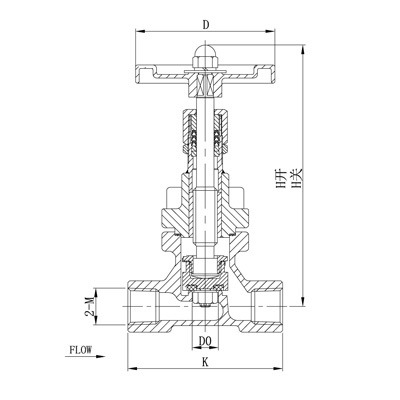

- Rising Stem with Outside Screw & Yoke

- Leakage Class

- Class VI or as specified

- Bonnet Type

- Extended Bonnet for Cryogenic Service

- Temperature Range

- -196°C to +80°C

- Body Design

- Angle / Straight Type Globe Valve

CRYOGENIC GLOBE VALVE DJ NPT Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 50 Kilograms Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About CRYOGENIC GLOBE VALVE DJ NPT

Nominal Pressure: 4.0Mpa

Design Temperature: -40AAAA A12A+80AAASuitable Media: O2, N2, Ar, NG,A CO2

Materials of Main Parts:

Body, Cover: CF8

Disc, Stem: S30408

Disc Seals: PTFE

Precision Engineered for Cryogenic Safety

This valve is meticulously designed for cryogenic environments, ensuring safe operation even under extreme temperatures. The extended bonnet and robust forging process enhance durability and insulation, making it dependable for handling substances like liquid oxygen and LNG.

Flexible and Reliable Material Choices

Crafted from high-quality stainless steel, CF8, and CF8M material, this globe valve offers excellent corrosion resistance and longevity. Its metallic silver finish and adherence to ASME B16.34 standards guarantee stability and safety in volatile cryogenic conditions.

FAQ's of CRYOGENIC GLOBE VALVE DJ NPT:

Q: How does the DJ NPT end connection benefit installation in cryogenic systems?

A: The Double Jointed NPT end connection allows for secure and leak-resistant assembly, simplifying installation and maintenance in cryogenic pipelines. It provides a reliable seal, which is critical for handling cold gases safely.Q: What is the recommended process for selecting between soft seat and metal seat types?

A: Soft seats are best for applications requiring tight shut-off and low leakage, while metal seats are preferable for conditions with higher temperatures, pressures, or abrasive media. Selection depends on your specific operational environment and required leakage class.Q: Where can the CRYOGENIC GLOBE VALVE DJ NPT be used?

A: This valve is suitable for industrial installations dealing with liquid oxygen, nitrogen, LNG, and various industrial gases. It is widely used in cryogenic service facilities and processing plants worldwide, including China.Q: When should I specify an extended bonnet for my globe valve?

A: An extended bonnet should be specified when the valve will operate at very low temperatures (down to -196C). It prevents heat transfer to the stem, reducing the risk of malfunction or leakage caused by thermal contraction.Q: How does the valve's testing to API 598 and BS 6755 standards ensure quality?

A: Testing to API 598 and BS 6755 verifies the valve's integrity, leak tightness, and structural performance, assuring users that the valve will perform reliably under specified conditions and meets global safety requirements.Q: How is manual, hand-operated control advantageous in cryogenic applications?

A: Manual control offers precise regulation of flow and is reliable in low-temperature environments, where automated systems may be less effective. It allows operators to respond quickly to process demands and maintain operational safety.Q: What are the main benefits of using forged stainless steel for the valve body?

A: Forged stainless steel provides exceptional strength, improved wall thickness per ASME B16.34, and enhances resistance to corrosion and thermal stress, resulting in longer service life and better performance for cryogenic duties.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in cryogenic globe valve Category

cryogenic globe valve DJ A1

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Noise Level : Low

Size : DN15 to DN300

Weight : Depends on size, approx. 4 kg (DN25)

Thickness : Body wall: 10 mm (typical)

cryogenic globe valve DZJ

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Noise Level : Low

Size : DN15 to DN300

Weight : Variable, according to size

Thickness : Customizable

cryogenic globe valve DJ 10PL 008

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Noise Level : Low

Size : DN8 (1/4 inch)

Weight : Approx. 1.2 kg

Thickness : Body thickness designed for cryogenic service

cryogenic globe valve DJ 10PA PB PC

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Noise Level : Low

Size : DN10 to DN200

Weight : Depends on Size

Thickness : Industry Standard

|

ZHANGJIAGANG GRANDE MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry