CRYOGENIC GLOBE VALVE DJ GA GK

CRYOGENIC GLOBE VALVE DJ GA GK Specification

- Material

- Stainless Steel / Carbon Steel / Alloy Steel

- Weight

- Varies with Size

- Thickness

- Standard as per Design

- Size

- 1/2 to 12 (DN15 to DN300)

- Control System

- Handwheel Operated

- Automatic Grade

- Manual

- Noise Level

- Low

- Color

- Silver / As per Requirement

- Capacity

- Depends on Valve Size (Customized)

- Processing Type

- Casting

- Application

- Cryogenic Services, LNG, Liquid Oxygen, Nitrogen, Hydrogen

- Stem Material

- Stainless Steel

- Pressure Rating

- Class 150/300/600

- Test Standard

- API 598

- Bonnet Type

- Extended Bonnet (Cryogenic Service)

- Design Standard

- BS 6364, API 602, ASME B16.34

- Leakage Class

- Class VI / Bubble Tight

- Body Type

- Straight / Angle Pattern

- Operation

- Manual (Handwheel), Actuated on request

- End Connection

- Flanged / Butt Weld / Socket Weld

- Temperature Range

- -196°C to +80°C

- Seat Material

- PTFE / Metal Seated

- Gland Packing

- PTFE / Graphite

- Port Type

- Full Port

CRYOGENIC GLOBE VALVE DJ GA GK Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 50 Kilograms Per Month

- Delivery Time

- 7 Days

About CRYOGENIC GLOBE VALVE DJ GA GK

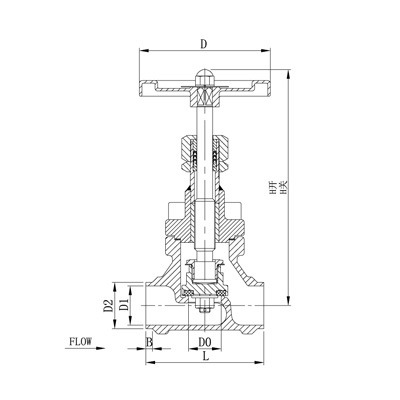

CRYOGENIC GLOBE VALVE DJ-GA/GK

Nominal Pressure: 4.0Mpa

Design Temperature: -40ai12+80a

Suitable Media: O2, N2, Ar, NG, CO2

Connection: Butt Weld

Materials of Main Parts:

Body, Cover: CF8

Disc, Stem: S30408

Disc Seals: PTFE

Precision Engineering for Extreme Conditions

Designed to perform reliably under demanding cryogenic conditions, the DJ GA GK globe valve supports operations between -196C and +80C. The extended bonnet ensures safe operation by maintaining gland packing above freezing, reducing risk of icing and enhancing long-term performance even in applications involving LNG and liquefied gases.

Versatile Connections and Superior Sealing

Available with flanged, butt weld, or socket weld ends, this globe valve integrates smoothly into various piping systems. Choose between PTFE or metal seats, with Class VI/bubble tight sealing for exceptional leak prevention. Its full port and low noise level promote efficient, quiet flow management across size ranges DN15 to DN300.

FAQ's of CRYOGENIC GLOBE VALVE DJ GA GK:

Q: How does the extended bonnet benefit cryogenic service applications?

A: The extended bonnet design provides thermal insulation by distancing gland packing from the cold process fluid, thus preventing freezing and ensuring reliable, long-term operation in low-temperature environments such as LNG, liquid oxygen, or nitrogen systems.Q: What standards does the CRYOGENIC GLOBE VALVE DJ GA GK adhere to?

A: The valve is manufactured in compliance with BS 6364, API 602, and ASME B16.34 design standards and undergoes rigorous testing as per API 598, which ensures performance, durability, and leakage integrity for critical cryogenic services.Q: When should I choose PTFE versus metal seated options for this valve?

A: PTFE seats are best suited for applications seeking superior sealing performance and resistance to aggressive chemicals, while metal seats are recommended for higher temperatures or abrasive conditions where increased durability is required.Q: Where is the CRYOGENIC GLOBE VALVE typically installed?

A: This valve is commonly installed in cryogenic processing plants, LNG facilities, storage terminals, and industries handling liquid oxygen, hydrogen, or nitrogen, where maintaining tight shutoff at very low temperatures is essential.Q: What is the process for customizing the valve for specific capacity or size requirements?

A: Customization depends on project specifications; you can request the required size (from 1/2" to 12"/DN15 to DN300) and material (stainless, carbon, or alloy steel). Capacity and connection types are tailored based on operating conditions, with technical consultation provided by the manufacturer or supplier.Q: How is the globe valve operated, and what actuation options are available?

A: Standard operation uses a manual handwheel, ensuring straightforward on-site control. For automation, actuated options can be requested, enabling integration into remote or automated process systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in cryogenic globe valve Category

cryogenic globe valve DJ A1

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Manual

Noise Level : Low

Size : DN15 to DN300

Thickness : Body wall: 10 mm (typical)

cryogenic globe valve DZJ

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Manual

Noise Level : Low

Size : DN15 to DN300

Thickness : Customizable

cryogenic globe valve DZJ 40J

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Manual

Noise Level : Low

Size : DN40 (40 mm)

Thickness : Body wall varied per pressure class

cryogenic globe valve DJ 10P3 5 6

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Unit

Automatic Grade : Manual

Noise Level : Low

Size : DN10 to DN50 (typically 3/8 2)

Thickness : Body thickness as per ASME/ANSI class standard (customized per rating)

|

ZHANGJIAGANG GRANDE MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry