cryogenic globe valve DGJ

cryogenic globe valve DGJ Specification

- Automatic Grade

- Manual

- Color

- Silver / Metallic

- Weight

- Varies by Size (approx. 6 kg to 120 kg)

- Thickness

- Up to DN 250

- Size

- DN 15 to DN 250

- Control System

- Hand Wheel Operated

- Noise Level

- Low

- Material

- Stainless Steel / Forged Steel

- Capacity

- High Flow Capacity

- Application

- LNG, Liquid Nitrogen, Liquid Oxygen, Cryogenic Gas Pipeline

- Processing Type

- Cryogenic Service

- Operation Type

- Manual / Optional Pneumatic Actuator

- Bonnet Type

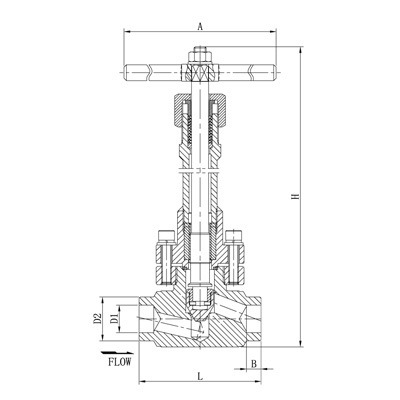

- Extended Bonnet for Cryogenic Use

- End Connection

- Flanged / Butt Weld / Socket Weld

- Testing

- Hydrostatic and Cryogenic Testing

- Trim Material

- Stainless Steel or Monel

- Pressure Rating

- Class 150 to Class 1500

- Leakage Rate

- Class VI (Bubble Tight)

- Temperature Range

- -196°C to +80°C

- Body Type

- Straight Pattern

- Design Standard

- BS, ASME, API

cryogenic globe valve DGJ Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- SHANGHAI

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden box

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Africa, Central America, Eastern Europe, Asia, North America

- Main Domestic Market

- All India

- Certifications

- CE

About cryogenic globe valve DGJ

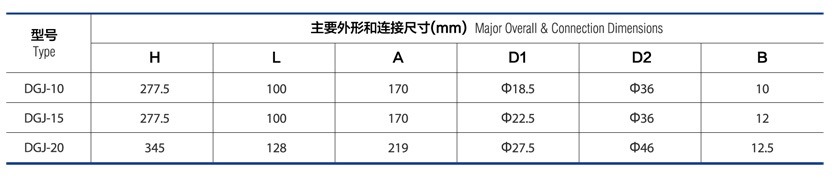

Nominal Pressure:32Mpa

Design Temperature: -196+80-Suitable Media: LNG, LO2, LN2, LAr

Connection: Socket Weld

Materials of Main Parts:

Body, Cover: S30408

Disc, Stem: S30408

Versatile Cryogenic Performance

This valve excels in low-temperature environments, from LNG facilities to laboratories handling liquid nitrogen and oxygen. Featuring robust stainless steel or forged steel construction, it ensures safety and reliability under extreme thermal conditions, maintaining precise flow control and a leak-proof seal at all rated pressures and connection types.

High Standards of Quality and Testing

Each DGJ globe valve undergoes rigorous hydrostatic and cryogenic testing to guarantee performance and durability. The extended bonnet design protects critical internal components, while compliance with international standards (BS, ASME, API) makes it a trusted choice for global projects.

Flexible Installations and Control Options

Engineered for adaptability, the DGJ valve accommodates both manual and pneumatic operations. Its body type supports high flow capacity while minimizing noise. Multiple end connections, sizes, and trim materials provide custom solutions for diverse industrial requirements.

FAQ's of cryogenic globe valve DGJ:

Q: How is the DGJ cryogenic globe valve installed in a cryogenic gas pipeline system?

A: Installation depends on the chosen end connection type-flanged, butt weld, or socket weld. The valve should be connected according to the pipeline configuration, ensuring the extended bonnet remains properly oriented for optimal insulation and performance in cryogenic environments.Q: What benefits does the extended bonnet offer for cryogenic service?

A: The extended bonnet acts as an insulating barrier, protecting valve packing and internal components from extreme cold. This design ensures reliable operation at temperatures as low as -196C, minimizing the risk of leakage and enhancing valve longevity.Q: Where can this valve be used within industrial processes?

A: The DGJ cryogenic globe valve is suitable for facilities processing LNG, liquid nitrogen, and liquid oxygen, as well as cryogenic gas pipelines. Its robust build and high flow capacity make it ideal for both distribution and storage applications.Q: What materials are available for the valve and trim, and how do they affect performance?

A: Valve bodies are offered in stainless steel or forged steel, ensuring durability. Trims are available in stainless steel or Monel, providing resistance to corrosion and wear in harsh cryogenic conditions, thereby extending service life.Q: When should a pneumatic actuator be considered for this valve?

A: A pneumatic actuator is recommended for remote operation, frequent cycling, or when manual access may be limited. This option enhances automation and process efficiency while maintaining safe operation in cryogenic services.Q: What testing processes are performed on the DGJ cryogenic globe valve?

A: Valves undergo hydrostatic and cryogenic testing to verify structural integrity, leak-tightness (Class VI bubble-tight), and functionality under both high-pressure and low-temperature conditions, ensuring compliance with industry standards.Q: How does the valve ensure noise reduction during operation?

A: The straight pattern body design and precision machining help minimize flow turbulence, resulting in lower noise levels even at high flow rates, contributing to a safer and quieter working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in cryogenic globe valve Category

cryogenic globe valve DZJ

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Application : LNG, air separation, cryogenic pipelines and storage

Capacity : High flow capacity

Processing Type : Forged

Control System : Handwheel operated

CRYOGENIC VALVE DJ 10PH PH1

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Unit

Application : LNG, Liquid Nitrogen, Cryogenic Storage

Capacity : Up to 20 bar

Processing Type : Cryogenic Valve

Control System : Hand Operated

CRYOGENIC GLOBE VALVE DJ GGY

Minimum Order Quantity : 1 Watt

Application : Cryogenic Service for LNG, Liquid Oxygen, Nitrogen, Hydrogen

Capacity : Up to DN600

Processing Type : Forged / Cast

Control System : Handwheel Operated

cryogenic globe valve DJS 25 A1

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Application : Cryogenic Service, LNG, Liquid Nitrogen, Oxygen, Argon Handling

Capacity : 25 mm (Port Size)

Processing Type : Forged

Control System : Handoperated

|

ZHANGJIAGANG GRANDE MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry