Cryogenic Check Valve Dhx

MOQ : 1 Piece

Cryogenic Check Valve Dhx Specification

- Noise Level

- Low

- Color

- Silver

- Automatic Grade

- Manual

- Weight

- Depends on size (typically 1-8 kg)

- Thickness

- Standard as per model

- Material

- Stainless Steel

- Processing Type

- Check Valve

- Application

- Cryogenic gases, LNG, liquid nitrogen, oxygen and other industrial gases

- Size

- DN15 to DN100 (1/2 to 4)

- Capacity

- Suitable for various flow rates

- Operation

- Non-return, self-acting

- End Connection

- Flanged or Butt Weld

- Mounting Position

- Horizontal or Vertical

- Pressure Rating

- Class 150/300/600

- Testing

- Hydrostatic and pneumatic tested

- Leakage Class

- Class VI (Bubble-tight)

- Temperature Rating

- -196°C to +80°C

- Valve Type

- Cryogenic Check Valve (DHX Series)

- Seat Material

- PTFE/Metal

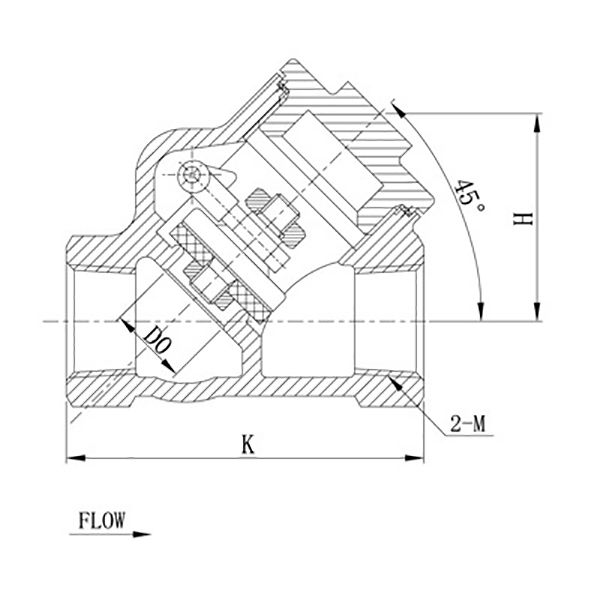

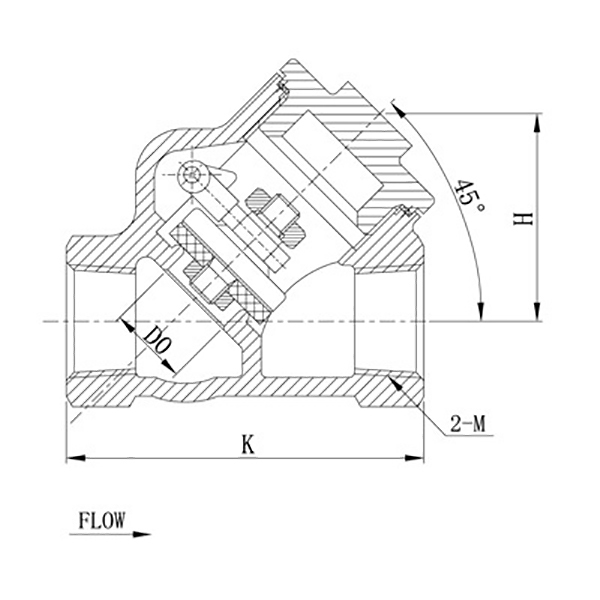

- Body Design

- Extended bonnet for low temperature insulation

Cryogenic Check Valve Dhx Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- SHANGHAI

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden box

- Main Export Market(s)

- South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Australia, Africa

- Main Domestic Market

- All India

- Certifications

- CE

About Cryogenic Check Valve Dhx

Discover the exclusive DHX Series Cryogenic Check Valve, your top-rated solution for controlling cryogenic gases like LNG, liquid nitrogen, and oxygen. Valued for its peerless reliability, this trending valve features an extended bonnet for low-temperature insulation, ensuring superior performance down to -196C. Designed with Class VI bubble-tight leakage and available in flanged or butt weld ends, it's engineered for various flow rates and applications. Manufactured from stainless steel, this best-in-class valve is a valuable asset for industrial settings requiring safe, dependable, and automatic non-return operation.

Versatile Commercial Applications for Cryogenic Check Valve DHX

The Cryogenic Check Valve DHX is extensively used in storage, transfer, and processing of cryogenic gases, including applications in LNG terminals, chemical plants, and gas distribution systems. Designed for both horizontal and vertical mounting, this valuable valve ensures safe, non-return flow in critical pipelines. Its peerless performance at extremely low temperatures makes it the best choice for industries dealing with liquid nitrogen, oxygen, and other industrial gases, ensuring continuous and secure operations.

Secure Shipping and Reliable Supply for Cryogenic Check Valve DHX

Benefit from secure shipping and on-time delivery of the DHX Cryogenic Check Valve at the lowest price from our supplier network in China. Our vast supply ability guarantees prompt order fulfillment for distributors, exporters, and manufacturers. Each valve is professionally packaged to ensure safety during transit, and clients benefit from flexible delivery times based on order size and destination, making the purchasing process hassle-free and dependable.

Versatile Commercial Applications for Cryogenic Check Valve DHX

The Cryogenic Check Valve DHX is extensively used in storage, transfer, and processing of cryogenic gases, including applications in LNG terminals, chemical plants, and gas distribution systems. Designed for both horizontal and vertical mounting, this valuable valve ensures safe, non-return flow in critical pipelines. Its peerless performance at extremely low temperatures makes it the best choice for industries dealing with liquid nitrogen, oxygen, and other industrial gases, ensuring continuous and secure operations.

Secure Shipping and Reliable Supply for Cryogenic Check Valve DHX

Benefit from secure shipping and on-time delivery of the DHX Cryogenic Check Valve at the lowest price from our supplier network in China. Our vast supply ability guarantees prompt order fulfillment for distributors, exporters, and manufacturers. Each valve is professionally packaged to ensure safety during transit, and clients benefit from flexible delivery times based on order size and destination, making the purchasing process hassle-free and dependable.

FAQ's of Cryogenic Check Valve Dhx:

Q: How does the Cryogenic Check Valve DHX prevent reverse flow in pipelines?

A: The DHX valve features a self-acting, non-return mechanism that automatically stops flow reversal, safeguarding your system from backflow during operation.Q: What materials are used in the construction of the DHX Cryogenic Check Valve?

A: The body is made from premium stainless steel, and the seat material options include PTFE or metal, providing exceptional durability and resistance to cryogenic temperatures.Q: Where can the DHX Cryogenic Check Valve be installed?

A: The DHX valve is designed for both horizontal and vertical mounting, making it versatile for use in various industrial setups such as LNG terminals, chemical plants, and gas processing units.Q: What is the typical delivery time for the DHX Cryogenic Check Valve?

A: Delivery times depend on order size and destination, but we prioritize secure shipping and strive for prompt delivery to ensure your operations run smoothly.Q: What leakage class does the DHX Cryogenic Check Valve offer?

A: This valve is rated for Class VI (bubble-tight) leakage, delivering peerless sealing performance suitable for critical cryogenic applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in CRYOGENIC CHECK VALVE Category

Check Valve Cryogenic Dhx

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Processing Type : Casting

Thickness : Standard

Automatic Grade : Manual

Cryogenic Check Valve Dh 80

Price Range 10.00 - 100.00 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel (SS 304/316), Brass

Processing Type : Cryogenic Application

Thickness : Standard Valve Body Thickness (per manufacturer specifications)

Automatic Grade : Manual

|

ZHANGJIAGANG GRANDE MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry