Carbonated Soft Drink Big Production Line

Carbonated Soft Drink Big Production Line Specification

- Product Type

- Carbonated Soft Drink Big Production Line

- Material

- Stainless Steel 304/316

- Application

- Carbonated Soft Drink Bottling

- Packaging Material

- PET bottles, Glass bottles, Aluminum cans

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Control System

- PLC (Programmable Logic Controller)

- Drive Type

- Electric

- Voltage

- 380V/50Hz (Customizable on request)

- Weight (kg)

- 9500 kg

- Dimension (L*W*H)

- 11000*2200*2300 mm

- Capacity

- 12000-24000 bottles/hour

- Feature

- High automation, user-friendly operation, energy-saving

- Color

- Silver

- Filling Method

- Counter Pressure Filling

- Cleaning System

- Automatic CIP (Clean-In-Place)

- Conveyor System

- Stainless steel modular belt

- Capping Heads

- 10 heads

- Bottle Height

- 150-340 mm

- Filling Heads

- 32-40 heads (customizable)

- Compress Air Pressure

- 0.6 MPa

- Rinsing Heads

- 32-40 heads (customizable)

- Main Motor Power

- 7.5 kW

- Suitable Cap Types

- Screw cap, Crown cap

- Production Environment

- Dust-free, food-grade compliant

- Water Consumption

- 1.5 m/h

- Bottle Diameter

- 50-110 mm

- Bottle Size Supported

- 250ml 2000ml

- Labeling Option

- Integrated labeling machine (optional)

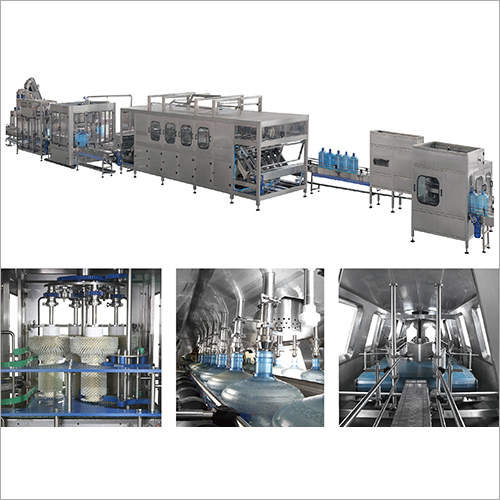

About Carbonated Soft Drink Big Production Line

Superior Performance for Beverage Leaders

Used by prominent carbonated drink producers and beverage distributors, this big production line boasts a gilt-edged reputation for reliability and versatility. The fully automatic machine features 32-40 customizable rinsing and filling heads, 10 capping heads, and a user-friendly PLC control system. Its stainless-steel structure, integrated cleaning, and dust-free, food-grade environment offer unmatched hygiene and efficiency, ensuring beverages retain their classic taste and eminent brand value with every batch.

Sample Availability and Professional Order Processing

Samples can be arranged to verify machine quality and efficiency before a full-scale purchase. Our supply ability ensures consistent, prompt order processing-even for large volumes. Orders are precisely packaged and carefully dispatched to maintain machine integrity in transit. Payment terms are designed for convenience, supporting international exporters, suppliers, and traders. The entire process, from initial inquiry to final delivery, is streamlined for speed, transparency, and customer satisfaction.

FAQ's of Carbonated Soft Drink Big Production Line:

Q: How does the counter pressure filling method benefit carbonated soft drink bottling?

A: The counter pressure filling method preserves carbonation by minimizing gas loss during filling, ensuring beverages maintain their fizz and quality. It is ideal for soft drink production lines that prioritize taste and freshness.Q: What bottle sizes and types can the production line accommodate?

A: This production line supports bottle sizes from 250ml to 2000ml and is compatible with PET bottles, glass bottles, and aluminum cans. The system efficiently handles bottle diameters between 50-110 mm and heights from 150-340 mm.Q: What features make this production line user-friendly?

A: Equipped with a computerized PLC control system, integrated automatic CIP cleaning, and a modular stainless steel conveyor, the machine offers high automation, easy operation, and minimal manual intervention, streamlining the entire bottling process.Q: When will my order be dispatched after payment?

A: Order processing begins immediately after payment confirmation. Due to robust supply ability, orders are typically dispatched promptly, with packaging designed to ensure safe delivery and accurate fulfillment based on client requirements.Q: Where is the production line manufactured and exported from?

A: The production line is manufactured in China and distributed globally by eminent exporters, suppliers, and traders. Customizations for voltage and specifications are available to meet local operational needs.Q: What are the primary competitive advantages of this production line?

A: Key advantages include high-speed bottling capacity (12,000-24,000 bottles per hour), energy-saving features, robust stainless-steel build, integrated labeling and cleaning systems, and compliance with food-grade, dust-free standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Beverage Filling Machine Category

Hot Beverage Filling Line

Price Range 10000.00 - 200000.00 USD ($) / Set

Minimum Order Quantity : 1 , , Set

Packaging Material : Other, Glass Plastic

Product Type : Filling Machine

Color : Silver

Hot Filling Machine 3-in-1 Monobloc

Price Range 10000.00 - 200000.00 USD ($) / Set

Minimum Order Quantity : 1 , , Set

Packaging Material : Other, Bottles

Product Type : Hot Filling Machine

Color : Silver

PET Bottled Soft Drink 3-in-1 Monobloc

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Set

Packaging Material : Other, PET Bottles

Product Type : Bottled Soft Drink 3in1 Monobloc

Color : Silver

5 Gallon Big Bottle Filling Line

Price 50000 USD ($) / Set

Minimum Order Quantity : 1 Set

Packaging Material : Other, Plastic (5gallon water bottles) or similar

Product Type : Water Bottle Filling Line

Color : Other, Metallic (Primarily Steel Grey)

|

ZHANGJIAGANG GRANDE MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry